All of the MacGregor powersailers have twin kick-up rudders that are used both for sailing and when the outboard is running, even at speed. On the M19, the motorwell is too narrow to allow the outboard to swing more than a few degrees. Unlike the later 26X and 26M models, the motor and the rudders are not connected together on the M19.

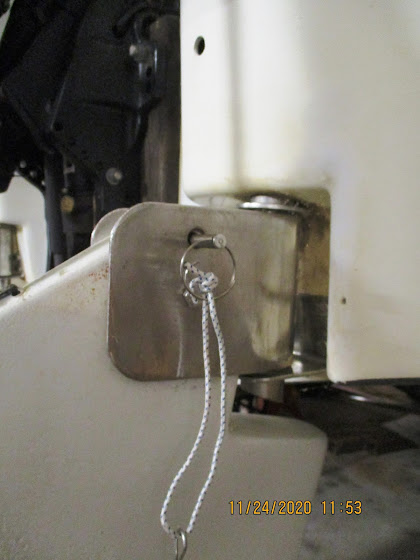

The kick-up rudder blades are hinged on custom stainless steel rudder posts. MacGregor used sacrificial plastic shear pins, nylon bolts, or wooden dowel pins to hold the hinged blades in the down position. The photo shows the rudder blade down, using the stainless steel "transport" pin (which I use to lock the blades up for trailering, not for sailing!).

Running aground breaks the plastic or wood pin and (hopefully) protects the steering mechanism and rudder blade from major damage. But with the blade up it's now nearly impossible to steer the boat, and the blade could even break if the boat is running at speed. In the worst case, the stress could rip out both the rudder and rudder post. Even though the original rudder blades are rather substantial construction, it looks like many M19 owners have replaced their rudder blades, for one reason or another. They are available from Blue Water Yachts (www.bwyachts.com), the aftermarket part supplier for MacGregor sailboats. Or from Ruddercraft (www.ruddercraft.com, only $559).

Why not just motorsail using the outboard to steer using it if the pins should shear? As mentioned above, on the M19 the 40-hp outboard can't swing more than a few degrees, and the motor is not connected to the tiller arm. Besides the issue with steering, how do you replace the pin when you're out on the water? And you don't have a boarding ladder? It would be prudent at this point to fire up the outboard, drop the sails, and motor back to a dock to effect the pin replacement.

The rudder shear pins have contradictory requirements: they must be strong enough to keep the rudders down while planing at full speed (according to the specs, up to 25 mph), but still able to shear through if you hit something solid. I did not expect the plastic pins that came with the boat to last very long on the Chesapeake Bay, particularly in the places where I gunkholed with my Potter 15. The spares included with the boat were clearly homemade home-brew replacements -- so it looked like I needed to devise an alternate approach. I definitely did not want to break a rudder blade, or a steering post ($185 for a replacement), or worse.

The original M19 rudder blades appear to be solid fiberglass and weigh about 14 pounds. Many of the more common 26-foot powersailers, and a few M19 owners, modified their blade systems and used multi-part uphaul and downhaul lines. However, this seemed much too complicated to me, and required a lot of parts and some machining. Instead, I borrowed a tried-and-true Potter mod -- the push-pull control rod -- which, according to Potter lore and typical of the breed, was originally conceived using a broken golf club handle (see, for example, Harry Gordon's or Wayne Pierce's “Rudder Blade Push-Pull Control Rod... " rudder modifications in the WW Potter Owners Association archive). My push-rod prototype was constructed using scrap wood and some scrap copper water tubing that was sitting in my shop. I attached a spare plastic bimini fitting to the top of each rudder blade, flattened the end of the copper tubing, and attached it to the fitting.

To top of the copper pipe is retained by a wood crosspiece, which has holes the the copper pipes that are drilled just slightly oversize, so there is some friction. It worked very well until I oiled the wood to protect it.

This modification is simple and cheap; but the rudders still would kick up when the boat was powered up and there was a lot of pressure on the blades. My contribution to the Potter mod is to rig the “golf clubs” with a thin line “stop” to hold the blades down. The lines are stretchy enough that if the rudder blades do connect with something, or if I drive the boat fast enough, they will lift a bit, but I will still have enough blade down to control the boat. Next I'm going to replace the wood crosspiece with some PVC lumber, and then I won't have to bother with varnishing or painting (the crosspiece above looks pretty ratty, after one season). I can think of many ways to control the friction between rods and the crosspiece, but all of them increase the parts count and complexity of the mod. So I will retain the line-cleat arrangement for now.

As I said earlier, during transport on the trailer I lock the rudder blades up using those stainless steel pins. The bottom of the rudder blades needed some touch up epoxy. Once the repairs cured, I buffed them up the lower part of the rudder blades with 50 grit sandpaper and spray painted them with "Kubota" orange spraypaint from my local hardware store.

No comments:

Post a Comment